Voortman inside technicians are often able to resolve any problem remotely. Voortman technicians can access your machine via an internet connection. Voortman equipment has a powerful Windows(r-based Siemens control which allows this capability and offers superior diagnostics through Windows(r).

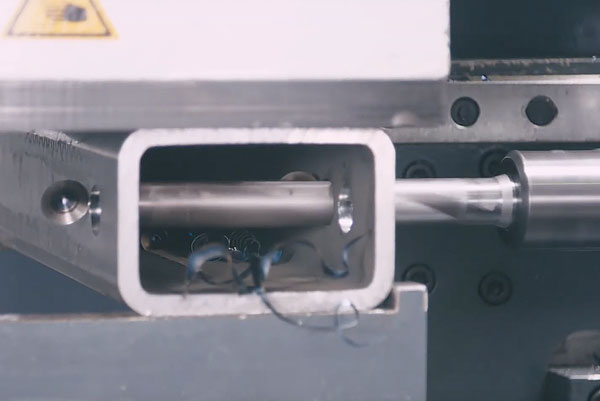

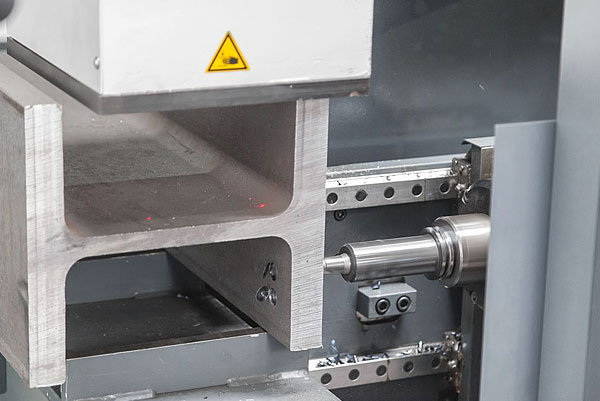

For 50 years we have been developing machines and solutions for you as a steel fabricator. We focus on automation as a response to the ever-decreasing ability to find quality labor and rising labor costs, so you can lower your overall production costs and increase your margins.You can ensure the utmost productivity, accuracy and reliability with one of Voortman�s CNC Beam Drill lines. Our CNC Beam Drill Lines integrate many functions like drilling, milling, marking, countersinking, thread-tapping and more to increase capacity and automation and optimize your workflow. Due to Voortman's complete range of advanced Beam Drill Lines, there is a suitable Beam Drill Line solution for every type of production or company.